|| STORE WIDE FREE SHIPPING || WGO AUTOMATIC GATE OPENER SYSTEMS WITH SECURE GATE ACCESS CONTROL OPTIONS ||

0

0

|| STORE WIDE FREE SHIPPING || WGO AUTOMATIC GATE OPENER SYSTEMS WITH SECURE GATE ACCESS CONTROL OPTIONS ||

0

0

Product SKU: APC-UG1400C-M

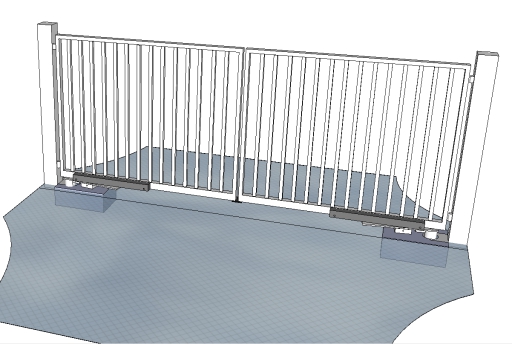

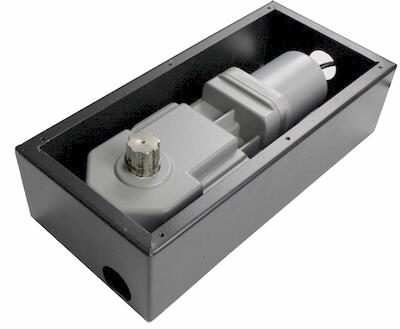

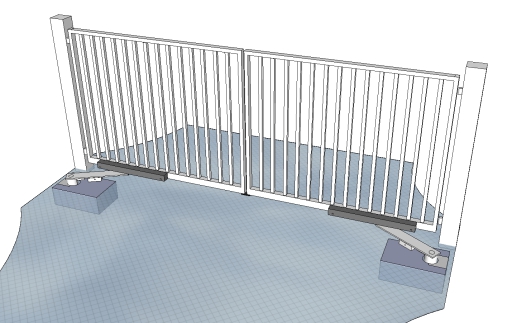

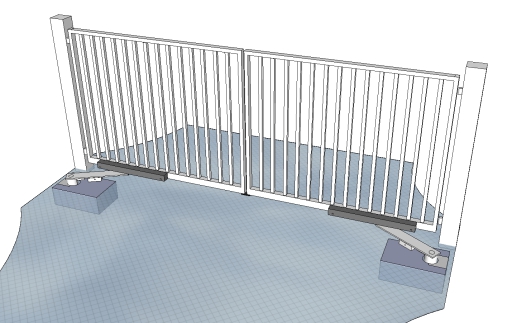

Extra Heavy Duty 24V DC Underground Replacement Motor

Please note: This product is for an Underground Gate Motor with a Foundation Box, Linking Arm and Drive Channel only to replace the existing APC underground gate opener system.

WARNING: This product is a replacement motor for an existing APC gate automation system. Warranty is only valid when used in conjunction with the APC equipment. No guarantee is given when used for another brand other than the APC brand. Please feel free to call us for further assistance if required.

Pulling to open (opening inwards) can be set to open each gate up to 120° (maximum recommended) however 130° to 160° is achievable as with underground systems there is no concern regarding the motor clashing with the gate.

Adjustable in drive channel stops are supplied with the kit if a completely discreet stop is preferred but can only be used up to a maximum of 100° open angle. External gate stop is also provided in this kit and are required for the open angle greater than 100°

Recommended option and the easiest on the operator will allow for 120°+ operation

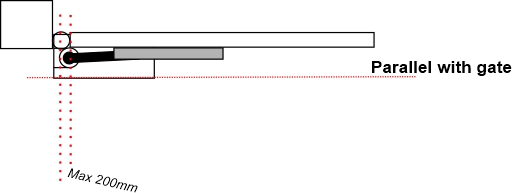

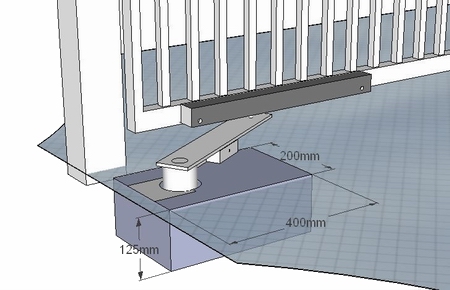

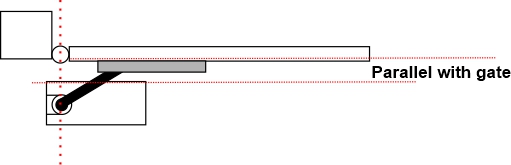

Center pivot of gate motor (output shaft) inline with the center of the gate pivot point (hinge), arm is at a 45° angle to the drive channel/gate

Maximum 100°, if option 1 cannot be used. Preferred over option 3

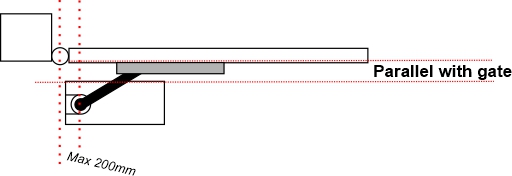

Center pivot of gate motor (output shaft) offset from the center of the gate pivot point (hinge) by up to 200mm, arm is at a 45° angle to the drive channel/gate

Maximum 90°, Hardest on the operator and should only be used in special circumstances as required.

Center pivot of gate motor (output shaft) offset from the center of the gate pivot point (hinge) by up to 200mm, arm is at a 20° angle to the drive channel/gate.